The new Miller Bobcat 230 is taking Miller engine driven welders to the next level. Watch the video below and keep reading to see how Miller has improved on one of their most popular engine drives.

User Friendly Improvements

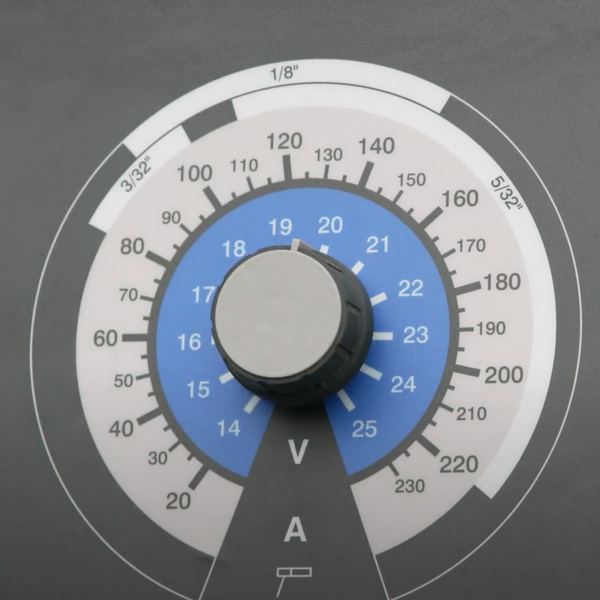

The Bobcat 230 has become easier to use than ever before. Miller has simplified the controls on the machine to a single knob that adjusts the amperage and voltage.

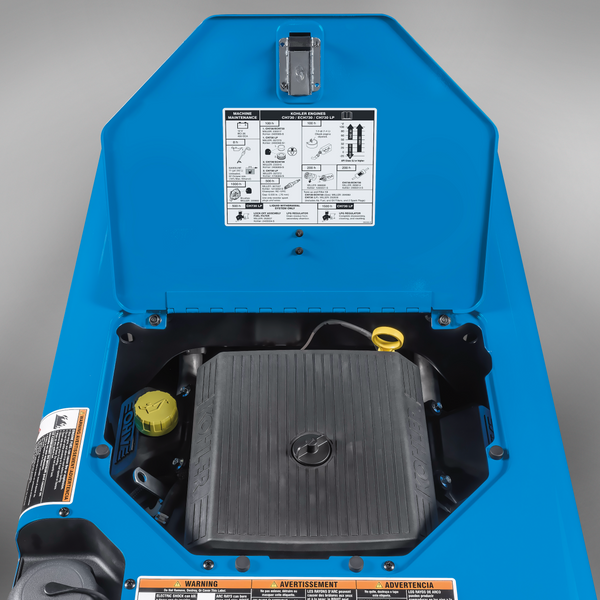

In addition to this, Miller has made the machine 100 pounds lighter and 13% smaller. That makes this machine easier to fit on trucks carrying other work tools and saving on fuel costs in the long run. The machine also has a digital fuel gauge with maintenance lights so it is easier to know when the machine needs to be serviced. The machine is easier to service due to improvements like the access door at the top of the machine for oil checks. Also, toolless panels that allow for quick access and single-side fuel fill and oil drain/filter

Power/Weld Improvements

On top of making the machine smaller and lighter, Miller also made the power easier to use and more consistent. The weld power and auxiliary power are separate from each other on this machine. This means one person can be welding and one person grinding from the machine, and the power will not dip for either user.

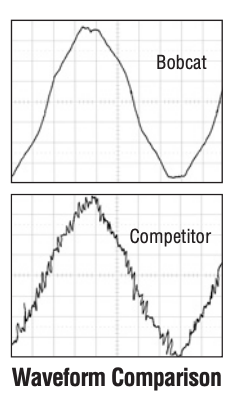

The power delivery is also smoother with zero arc interaction, which means there are no power spikes. Giving the user easier arc starts and less spatter when stick welding. A revolutionary ten-degree skewed-rotor design optimizes auxiliary power performance for smoother power — not spiked power.

On top of this, Millers Accu-Rated peak power of 11,000 watts is delivered for at least 30 seconds. Giving you a longer window of peak power over the competitions engine drives. This power can be useful for running a plasma cutter or MIG welder from the power the machine delivers.

The Bobcat 230 carries the Miller name so you know it will be reliable. Miller does a lot to make sure their engine drives are reliable and long lasting. A few are listed below.

- Copper windings and robust internal components for a quality-built machine

- Lugged - not soldered heavy internal leads for better field durability

- Superior cooling- technology for maximum performance and engine life

- Protective doors to cover the weld studs and receptacles as required by OSHA and CSA for jobsite safety

- Lift hook integrated into the center frame, which bolts to the machine’s base for greater durability.

Overall the Bobcat 230 is a great update over the popular Bobcat 225. Every improvement and feature added makes the weld operators job easier to accomplish. If you have any questions on the Bobcat 230 or are looking to get one, reach out to our support team. support can be reached at 877-930-5690 or by emailing support@bakersgas.com.